Estimated reading time 5 minutes, 44 seconds.

Canada is a world leader in aerospace design and manufacturing, maintenance repair & overhaul (MRO), and space systems. In Western Canada, Manitoba has the largest aerospace cluster, behind only Montreal and Toronto in Canada. Even with 40 companies with more than 5,000 employees and $1.6 billion in sales (80 per cent exported), Manitoba is small in the fiercely competitive global supply chain. To continue as a full participant in the rising market for new aircraft, space systems and aircraft servicing, in an industry driven by technology and innovation, Manitoba Aerospace set out to identify the key technologies needed to provide a sustainable long- term competitive advantage.

Six Thrust Area Working Groups (TAWGs), coordinated by a Steering Committee, identified 25 key technologies. These provide a framework reached in collaborative consensus to define a Technology Road Map (TRM) that will provide direction for technology development programs. The TRM continues work begun with the Emerson 2012 report on aerospace and is aligned with the national Technology and Innovation Committee operating under the Aerospace Industries Association of Canada (AIAC).

While supported by academic, research and government agencies, the TRM development was driven by industry, led by Kim Olson, senior vice president StandardAero. Aerospace R&D is costly and long-term and therefore requires collaboration regionally, nationally and even internationally. The competitor is not the company down the street; the competitors are in Singapore, Korea and, increasingly, Mexico.

The Manitoba Aerospace TRM was released Feb. 20, 2014, with over 50 industry members participating in the workshop.

TAWG 1 focussed on Advanced Machining. “Tool-making” has come a long way since the lathe was introduced in high school shops. Additive manufacturing includes the 3D printing we see in the news; automated 3D scanning of parts supports ultra-precise and fast inspection and measurement; while high speed and adaptive (intelligent) machining make increasingly complex production possible and efficient. Strides are also being made in non-destructive testing, and even nanotechnology is driving new opportunities in aerospace materials.

TAWG 2 examined technology development in Robotics and Automation. Today’s “tool-maker” is as much a computer scientist as an artisan. Not only are robots more dependable and accurate, they are especially useful in hazardous environments. One example cited was finishing the wing of a 787 in two days versus five, and with 80 pounds less paint.

The TAWG 3 focus on Composites struck me as old hat, with composite manufacturing long being a Manitoba strength, led by the Composites Innovation Centre that supports industries including bus manufacturing and medical devices, as well as aerospace. Boeing in Winnipeg only recently completed enhancements to handle work it had won for the 787 line, but has now announced a major expansion of its Winnipeg plant to handle new 737X work; and Magellan makes very precise and sophisticated composite parts for the F35 program. However, I learned that new technologies are turning composites on their ear. Aerospace parts manufacture has always required large – and expensive – autoclaves for high pressure, high heat curing. New technologies are allowing “out-of-autoclave” curing. Meanwhile, new high temperature composites are used in the fan blades of the newest jet engines.

TAWG 4’s mandate was Simulation Modelling and Analysis, which involves enhanced training technologies including virtual reality, to reduce training cost and time with higher competency. Simulation technologies are being used to test complex interconnected systems, while modelling of new materials can provide data to designers and regulators more economically than building prototypes for destructive testing.

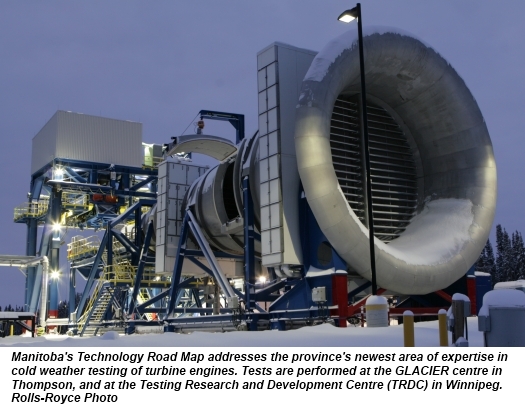

TAWG 5 on Testing and Certification addressed growing Manitoba’s newest area of expertise in cold weather testing of turbine engines at the GLACIER centre in Thompson and the Testing Research and Development Centre (TRDC) collaboration by StandardAero and General Electric in Winnipeg. The future development in this sector is in more sophisticated testing of a wider range of certification processes.

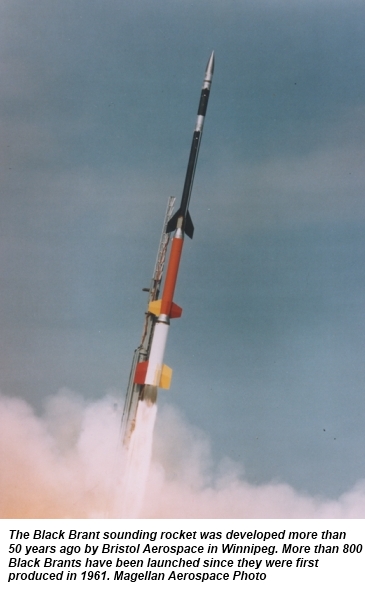

Finally, TAWG 6 looked at Space and Rocket Systems, a Manitoba area of specialty since Magellan Aerospace of Winnipeg (formerly Bristol Aerospace) developed its Black Brant rocket program more than 50 years ago, with the latest versions still in demand for space research, as well as satellites with continuing launches and programs. Unmanned Aerial Vehicles could not be left out, with Manitoba’s Micro-Pilot being a leading provider of UAV control systems.

For a more complete description of the 25 technologies making up the Manitoba TRM, the summary and full report are available at www.envirotrec.ca/projects.

The workshop concluded with a “Next Steps” session. The intent is to continue the TRM collaboration under the Manitoba Aerospace Association for governance and industry alignment. The next steps will be renewing the membership under a term of reference to continue the collaborative journey. That will begin by defining select technology demonstration projects with near term horizons, towards establishing a successful track record for the TRM model.