Estimated reading time 9 minutes, 17 seconds.

Tom Jackson does not remember exactly when he began tagging along with his father Ron, an aircraft mechanic for Okanagan Helicopters and later Canadian Helicopter Corporation, in the picturesque city of Fort St. John, British Columbia.

But Jackson was so young at the time that his memories do not go back much further. He grew up in and around the Okanagan hangar, playing with nuts and bolts and later spending his summers in fire camps, washing and waxing Bell 204 and 205 helicopters. As he worked, Jackson soaked in a corporate culture that struck him as the way to run a business — one that was family-oriented, focused on people, and where camaraderie was high.

It was exactly the kind of environment he wanted to replicate years later, when he created CanWest Aerospace, an elite maintenance, repair, and overhaul (MRO) firm based in Langley, British Columbia, about 28 miles (45 kilometers) southeast of Vancouver.

“I take that exact same business model and run it here, because it’s all I know,” said Jackson, a trained aircraft maintenance engineer who now serves as president and director of maintenance for CanWest Aerospace. “Everybody was one big family. They worked, they played, they hung out together. Their social network was the people they worked with.”

Jackson worked for about five years at CHC Helicopter, the

company that formed in 1987 after the merger of Okanagan, Toronto Helicopters, and Sealand Helicopters. He also spent time at Alpine Helicopters in Western Canada and worked as a private contractor in Central and South America, with stints at his father’s company, RTD Helicopter Support, and at Maxcraft Avionics, sprinkled in.

“I’ve been in the industry for so long now that I noticed that it changed,” he said. “We lost that family kind of thing. . . . Contractors and seasonal workers would come in and out, and people didn’t stay at one company for a long-term period. So, a lot of my people that work for me are long-term employees. They buy into the dream and the passion. And when they buy into that, then that transfers into the quality of work that you deliver to your customer on the MRO side.”

CanWest Aerospace traces its origins back to CanAm Components, a component overhaul business specializing in cargo hooks and aircraft accessories that Jackson started in a 350-square-foot space in a Langley industrial park in 2004. The company was initially part of CanAm Aerospace Group, and Jackson was its only employee. Within three months he hired a second worker, and the company grew quickly from there. It separated from CanAm Aerospace Group in 2006, re-branded as CanWest Components, and began buying up smaller companies that expanded its reach and scope of operations.

CanWest acquired River’s Edge Avionics in 2008 and bought its first hangar at Langley Regional Airport from Tundra Helicopters in 2009. The company increased its capabilities in dynamic components, hydraulics, pneumatics and wheels, and bought the assets of Precision Aero Instruments in 2011. Jackson decided to combine all three companies into one, and they became CanWest Aerospace in 2013. Growth continued with the acquisition of G Direct Aviation (formerly known as Nivens Aviation) in 2015.

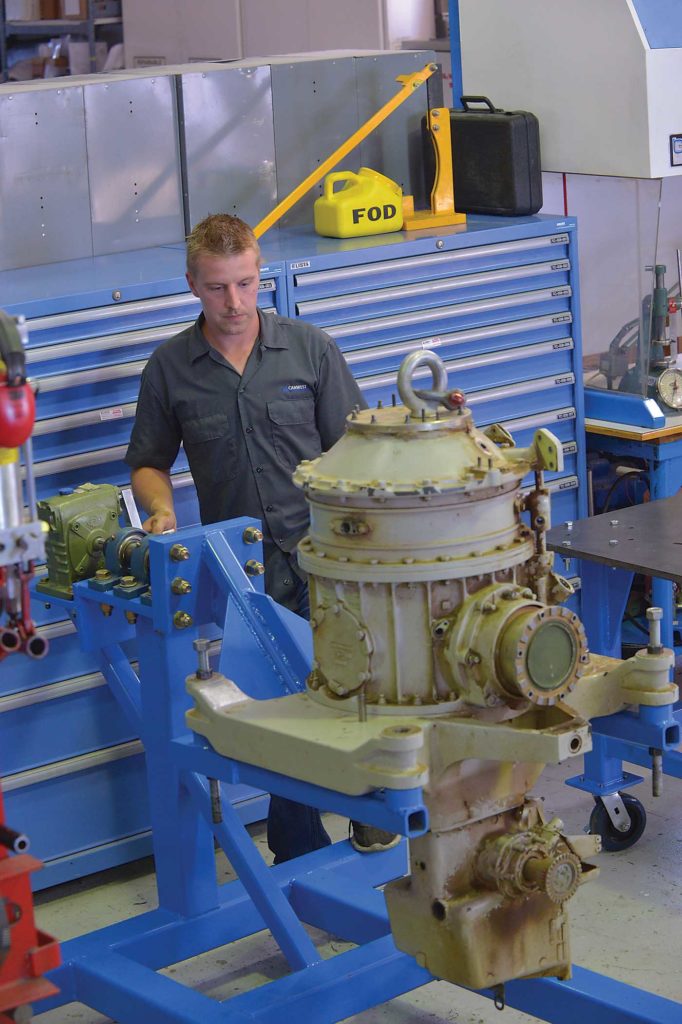

Today, CanWest Aerospace is one of North America’s premier independent MRO companies, supporting helicopter and fixed-wing customers around the world. Operating out of three buildings with about 18,000 square feet at Langley Regional Airport, the company has more than 40 employees, and is a Transport Canada and European Aviation Safety Agency (EASA) approved MRO provider with ISO AS9100D certification.

CanWest Aerospace offers comprehensive support to many of the most common light, medium and heavy helicopters, including the Sikorsky S-61 series, S-76, S-64, S-70, UH-60, UH-3H, SH-3D and CH-124; the Airbus Helicopters AS350, EC120 and Bo.105; the MD Helicopters MD 500; the Leonardo AW139; and the Bell Helicopter 206, 206L, 204, 205, 212, 214, 407, 412, CH-146 and UH series.

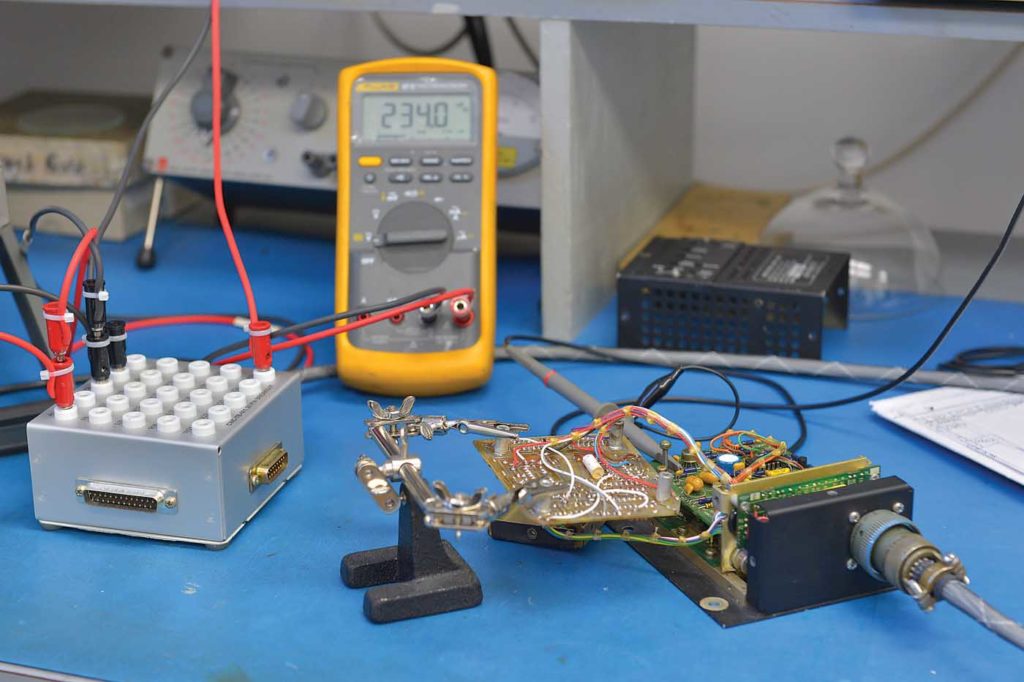

CanWest’s component MRO business offers support for everything from dynamic components like main and tail rotor drivetrains to electrical components, parts and assemblies like caution panels and search and landing lights. The company also repairs and overhauls flight controls, fuel systems, hydraulic and pneumatic components and systems, as well as landing gear components and magnetos. It also provides mechanical support services and continues to offer support for cargo hooks, wheels and brakes.

CanWest also has extensive repair, overhaul and field maintenance capabilities for airframes, offering full sheet metal, metal fabrication and composite services at its Langley facility or wherever operators are stationed around the world. Its customers include utility, offshore and aeromedical operators, as well as military and government agencies.

The company sees its avionics team as one of the best in the business, supported by some of the aviation industry’s leading original equipment manufacturers (OEMs) and distributors. Its comprehensive support includes troubleshooting and repair, new system installations and legacy integrations, avionics system upgrades, re-certifications and many other services.

Other key offerings include the company’s instrument repair and overhaul services, covering everything from tachometers and temperature indicators, to compasses and gyroscopic instruments. Rounding out its capabilities are CanWest’s wide range of fabrication and repair services for doors and cowlings, airstair doors, windows, platforms, elevators, intake plenums, firewalls, vertical and horizontal stabilizers, and panel reconstruction.

With such a wide range of services, CanWest believes it can refurbish aircraft to the point they’re not only as good as new — they’re even better.

“We pride ourselves [on] being legacy aircraft experts,” said Jackson. “As newer aircraft come off the production line, the focus on the OEMs is just supporting those newer aircraft.”

CanWest fills an essential niche, but it often runs into obsolescence issues, creating the need to either come up with new processes for repairs or manufacture new parts.

“As a small company we’re able to take on projects like that, that the OEMs may not have any interest in, because it’s an old, legacy aircraft,” said Jackson. “Their focus is on producing new aircraft and maintaining the current issues with their new fleets, not the old legacy programs.”

About 90 percent of the company’s work is for customers outside Canada, and providing on-site service is a key part of its approach. The CanWest global task force (GTF) travels virtually anywhere in the world to carry out repairs, often for practical reasons — it’s not always financially feasible to ship an aircraft to Langley. But it’s a measure that also vastly improves customer service.

“We can have someone on an airplane within 24 hours and on site, carrying out repairs and work,” said Jackson. “We’ve done operations in the Middle East, Africa, U.S., U.K., Asia, South America and Central America — literally almost all over the globe in many different working environments, both commercial and military operations.”

CanWest’s GTF also incorporates training into its deployments, passing on the decades of knowledge and experience that have made it an industry leader.

“We work with them so they can develop and learn these maintenance techniques — so they can better support their aircraft in-country,” said Jackson. “That’s kind of the heart of why the GTF exists — it’s also giving back to the industry.”

Another recent endeavor was the creation of CanWest Global AirParts, a sister company that offers an extensive, competitively priced catalogue of top-quality new and re-certified components. AirParts offers wheels and brakes, landing gear, avionics and instruments, flight controls, electrical items and spares, all stored in-house to ensure fast turnaround times.

“I learned the parts business from a very iconic parts company,” said Jackson, referring to his part-time job at Canadian Air Parts when he was in technical school in the mid-1990s. “I created the parts company [at CanWest] to be kind of a one-stop shop for our customers,” he added. “And we were able to pass on the savings to our clients on the parts sales side because we have the MRO capability to do all the components and recertification and repairs in-house.”

CanWest Aerospace continues to grow, albeit in cautious, strategic ways.

The company is in the process of creating a new 20,000-square-foot building that will be its new base, but the goal is to stay small enough to maintain the quality of work that produced its success, as well as strong relationships with customers.

“At the end of the day, we’re here for the long run,” said Jackson. “This isn’t just a business for us. It’s my life. It’s my passion, and I want to be able to look back like my dad is — who’s been in it for 40 years — and say that I’ve been in it just as long. And you know what? It’s been one of the best jobs I’ve ever had. I can’t think of anything else I’d ever want to do.”

Aviation’s hierarchical ; Money, Mechanics and Crews, period.

I’ve known Ron since tech school at Burnaby in 1971. We apprenticed together at Alpine Helicopters and our paths crossed many times since.. Its good to see that his excellent work is being furthered by son Tom.