Estimated reading time 10 minutes, 38 seconds.

Editor’s Note: Is your corporate aircraft looking a little tired these days? Have you ever wondered what’s involved in a custom refurbishment? We invited Peterborough, Ont.-based Flying Colours Corp. to walk us through a project that illustrates the custom design process, with a twist. In the first installment of this two-part series, we learn how a made-to-order plan and pre-engineered components combine to create a stunning, high tech Global Express interior that is both faster and less costly to install.

As residual aircraft prices remain low, many owners are choosing to keep their existing airplane rather than upgrade to a newer model. Continued economic uncertainty, a fluctuating dollar, and a glut of inventory in both the new and pre-owned aircraft sectors has also dampened enthusiasm for new aircraft purchases. However, there is a silver lining, as owners and operators recognize the opportunities presented by the increasingly sophisticated refurbishment and overhaul market.

Savvy individuals understand the value of purchasing a well-priced pre-owned aircraft, conducting a full maintenance review, and giving the cabin a facelift through the installation of a customized interior to satisfy their specific mission.

Innovations in the business jet interior sector continue to move at the speed of technology. In-flight entertainment and connectivity solutions are beginning to reflect offerings on the ground; while a mounting range of soft materials, leathers, wood veneers, and contemporary compounds such as carbon fibre, or millimetre-thin stone veneers, are being cleverly amalgamated to create striking and unique cabins.

Add to this the growing number of design houses and brands–for example Hermes, Alberto Pinto, BMW, and Porsche–that have stepped up to the interiors plate, and cabin refurbishments are an incredibly attractive option.

One of the latest innovations to come to market is the blending of customized design with pre-engineered components. Flying Colours Corp., the Canadian family-run international refurbishments company, is working with Inairvation, the 50/50 joint venture between Lufthansa Technik AG (LHT) and Austria’s F/List components and furniture GmbH, to deliver one such offering.

The Inairvation approach focuses exclusively on the development, marketing, and sales of technologically integrated, integrally designed cabin systems for business jet interiors. These pre-engineered components have been designed to fit into certain aircraft types, including classic Bombardier Global Express jets as well as Bombardier Challenger 300 and 605 models, along with Gulfstream G450 and Gulfstream G550 aircraft. This prêt-a-porter, rather than haute couture, offering can reduce cost and time for those looking to restyle their cabin within a certain budget and tight timeframe.

Flying Colours Corp. is one of the few North American partners selected by Inairvation to install these interior components, and the first company to sign a customer up.

“Our client completely understood that taking this route for his refurbishment would save him time and maximize his budget,” said Sean Gillespie, executive vice-president at Flying Colours. “An individual design created by our own in-house design team in Peterborough incorporates a number of the pre-engineered components from Inairvation’s offering. This allowed us to create a cabin that matches his very individual style and personal vision, yet one that could be installed, completed and fulfilled within a specified time and budget.”

The process

The project began with lengthy discussions between the internal design team, the client, and the design engineering experts from the Peterborough facility, where the work is ongoing.

“We have worked with this particular client on several projects and he has grown to trust us when we make recommendations. This strong and long relationship was a real advantage when detailing this particular concept,” noted Gillespie.

He explained that the customer, who already owns a number of pre-owned aircraft, exemplifies the current trend for buyers seeking the best value option on the market.

“The rate of requests for cabin overhauls is on the rise, which we believe reflects the current sales landscape in North America, Europe and Asia,” explained Gillespie. “A reconfigured aircraft can often fulfil the needs of an owner at a lower budget and in a shorter time. Add in the benefits of the pre-engineered solution and we can deliver a truly customized aircraft, designed to meet specific needs, in a timeframe and budget that is often considerably lower than a new aircraft purchase.”

Flying Colours is now about midway through the five-month refurbishment project and is transforming the client’s classic 2003 Bombardier Global Express cabin into a thoroughly breathtaking interior. The baseline Inairvation components are just one piece of the much larger cabin refurbishment project, but down time is reduced by maximizing the non-recurring engineering costs.

“The aircraft is undergoing extensive reconfiguration inside and out. Once we are finished it will look as if it has just come off the production line,” said Gillespie.

The design

Over a series of meetings, Flying Colours ensured the Global Express owner fully grasped the new Inairvation concept, and how it could be combined with the company’s established in-house capabilities to deliver the desired results.

The final design scheme is the result of a collation of ideas from Kate Ahrens, VP Design at Flying Colours, her team, and the client himself.

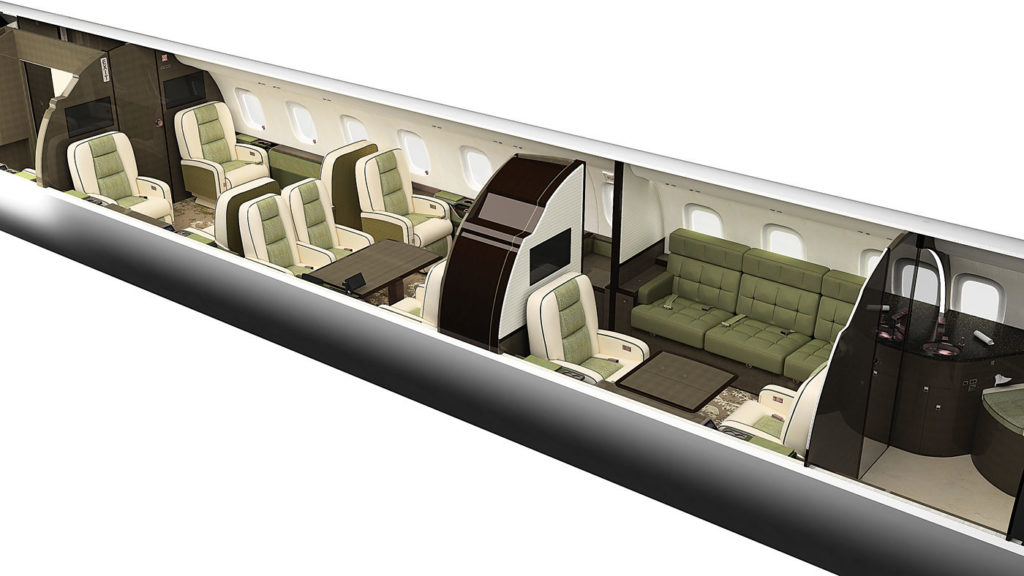

“The process involved three design iterations. Initially, we used a physical sample board to explore and select specific colours, which were informed by a green palette,” recounted Ahrens. “The materials included some really unusual textures which we also sampled with the client. Once these had been selected, we were able to consider how to collate everything for the desired effect of the overall project concept. We then used a 3D software system to render images of the final look. It helped us all to see what our final ideas could look like. Using this method, we realized the vision of contemporary elegance that combines with form and functionality to create an extremely comfortable cabin.”

The final plan was fixed in July 2016 ahead of the aircraft arriving at Flying Colours the following November.

An intoxicating collection of material textures and green and beige hues blend with an unusual brown carbon fibre finish to create the feel of a commodious cabin. The seat design is a good example of how Ahrens and her team exercised an incomparable attention to detail.

“Townsend Leather has been the inspiration for the seats,” said Ahrens about the new Global 6000 B/E Aerospace seat frame coverings. Classic

cowhide in a pale beige is predominant, but the detailing provides the desired sophistication. The seat insert is also in Expressions cowhide embossed with a cardamom-coloured American gator pattern. The top of the lower side walls and the seat side ledges emulate the cardamom hue and incorporate a chain link pattern.

The bottom of the lower sidewall is in Taj cowhide in the colour Kelly green, which is also being used for the piping. To complement the intricate selection of colours the seat back, armrest and vertical back band of the armrest feature a textured material known as Aniline Gaufrange, which is an embossed and hand-rubbed cowhide, featuring a cypress tone and a Moroccan pattern. Not only are the seats beautiful to look at, they are extremely comfortable and can be fully reclined.

The carbon fibre veneer further demonstrates the design intricacy as it features a brown twill pattern which breathes life into the surfaces it covers.

“While stunning, the pattern and material are quite challenging to work with,” said Ahrens. “We have had experience with carbon fibre but we still had to test, research and literally trial working with the material to make sure it would live up to expectations.”

Unlike many cabin surfaces where wood veneers predominate, the carbon fibre veneers cover the main surface areas including the tables, lavatory vanities, and pre-engineered side ledges. It is accented with a contemporary dark ebony hardwood.

The aircraft’s lighting will add atmosphere via a rainbow spectrum of mood colours, all controlled by the Lufthansa Technik nice HD in-flight entertainment and cabin management system (IFE/CMS), which is integrated into the Inairvation components.

“We’ve used B/E Aerospace LED lighting which features a Quasar-coloured spectrum that enables a varied ambience within the cabin. This is perfect for accommodating all the phases of the range of this aircraft,” said Ahrens.

A powerful first impression is created for any passenger boarding the jet by the dramatic contrast between the F/List crème-coloured stone granite floor and the F/List black granite countertop.

“This is a really striking feature and one that repeats in the forward and aft lavatories. Combined with the carbon fibre veneers the effect is spectacular,” said Ahrens.

In the cabin the pre-engineered side ledges, which incorporate the IFE/CMS, will be dropped into place. The baseline package includes an advanced user interface, a wireless interface for personal device integration–both iOS and Android–and a Hollywood studio content service with leading blockbuster movies and TV shows. The ergonomic side ledges will then be enclosed with the carbon fibre veneers to match the rest of the aircraft. All the elements have already been through rigorous design, testing and development, so the client does not have to wait, or pay, for this part of the process.

In addition to the comprehensive IFE system, a completely new Gogo ATG 5000 high-speed data system will be used to improve the existing cabin connectivity.

“The need for reliable connectivity is becoming a significant element to consider when it comes to cabin upgrades,” said Gillespie of the growing demand within the business aviation sector. “Customers are no longer satisfied with simply being able to make a phone call from the aircraft. They want Internet, Wi-Fi, email and constant communications with their business, family and friends. With this system in place, the client will be able to stay in contact while flying across the U.S., as well as parts of Canada and Alaska.”

This innovative blending of an individually customized design with elements that have been pre-designed for a particular aircraft type is an unusual approach to aircraft refurbishment. However, with more and more owners looking for an increased range of options to satisfy their executive aircraft needs, it is likely to become a model that others will follow.

It has not been without its challenges to create such an interior. In Part Two, we will consider the complexities of the installation and what it takes to make the concept a reality inside and out, as we review the installation process, truly unique external paint work, and the final interior completion itself.

Jane Stanbury is director of marketing and communications at Flying Colours Corp.