Estimated reading time 5 minutes, 34 seconds.

Boom Supersonic, an aerospace company working towards building the world’s fastest and most sustainable supersonic airliner, announced on Dec. 13 that it has partnered with three industry leaders to develop a new propulsion system for its Overture airliner.

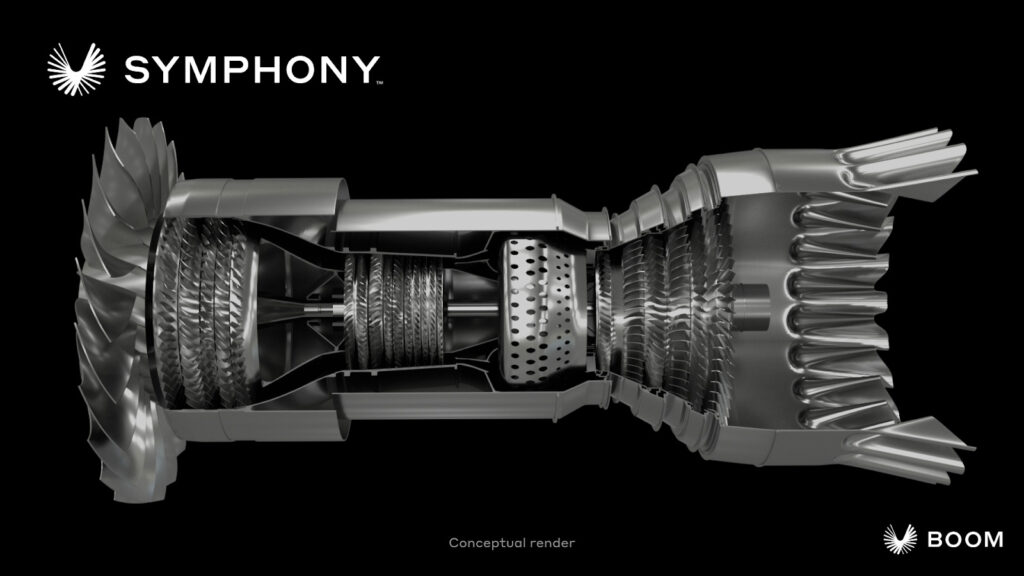

Boom is calling the new engine “Symphony,” and is teaming up with Florida Turbine Technologies (FTT), GE Additive, and StandardAero to make Symphony a reality. Boom says Symphony will be a medium-bypass turbofan engine (no afterburner), “with the same basic engine architecture that currently powers all modern commercial aircraft.”

However, it will differ from subsonic turbofans in a few ways. Symphony is to include a Boom-designed axisymmetric supersonic intake, a variable-geometry low-noise exhaust nozzle, and a passively cooled high-pressure turbine.

FTT was selected to assist Boom with the engine design, as the company has a wealth of supersonic engine design expertise — including engineers who were among the team that designed the supersonic engines that power the F-22 and F-35 fighter jets.

GE Additive, a division of General Electric that specializes in metal additive design and manufacturing, will provide additive technology design consulting on the Symphony program.

Lastly, StandardAero, an independent maintenance, repair, and overhaul (MRO) provider, will offer maintenance support.

The new engine, which is expected to deliver 35,000 pounds of thrust at takeoff, has been described by Boom as cost-efficient and sustainable.

“When compared to derivative approaches, Symphony is expected to deliver a 25 percent increase in time on wing and significantly lower engine maintenance costs, reducing overall airplane operating costs for airline customers by 10 percent,” the company said.

Symphony is also optimized for 100 percent sustainable aviation fuel — keeping the design in line with the various sustainability goals set by the aviation industry.

“Developing a supersonic engine specifically for Overture offers by far the best value proposition for our customers,” noted Blake Scholl, founder and CEO of Boom Supersonic. “Through the Symphony program, we can provide our customers with an economically and environmentally sustainable supersonic airplane — a combination unattainable with the current constraints of derivative engines and industry norms.”

The Symphony engine design, which is already underway, is to be compliant with FAA and EASA Part 33 requirements, according to the manufacturer.

This past July, Boom revealed the production design for Overture, stating that the aircraft is to have four wing-mounted engines and carry 65 to 80 passengers “at twice the speed of today’s airliners.” The aircraft will be capable of flying Mach 1.7 over water and Mach 0.94 over land, with a 4,250-nautical-mile range (with full payload).

To date, Overture’s commercial order book stands at 130 aircraft, which includes a recent deal with American Airlines for 20 Overture planes with an option for an additional 40, as well as purchases and options from United Airlines and Japan Airlines.

According to Boom, Overture is on track to achieve type certification in 2029. Production of the supersonic commercial aircraft is slated to begin in 2024 at the Greensboro-based Overture Superfactory, with rollout in 2026, and first flight in 2027.