Estimated reading time 8 minutes, 31 seconds.

For Lorenzo Marandola, president and founder of Laval, Quebec-based M1 Composites, it’s hard to believe the company is celebrating its 10-year anniversary in 2022.

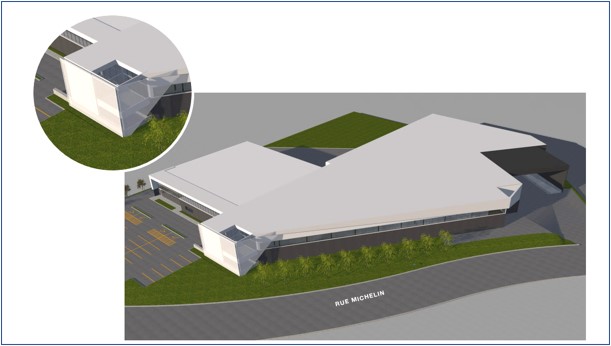

The last 10 years have seen M1 grow from just three employees to upwards of 75, and triple the size of its facility in a major expansion project.

“We’re now up to 82,000 square feet, and we’ve become a ‘go-to’ in terms of the specialty that we have for nacelles, flight control surfaces, and radomes here in Canada,” said Marandola.

When M1 Composites was established in October 2012, Air Canada chose the Quebec company to provide support with specific aircraft repairs. It started with minor composite repairs like overhead bins or lavatory components, and gradually moved to more complex parts such as nacelle inlet cowlings and thrust reversers as M1 proved its capabilities.

Today, the company has established itself as an Approved Maintenance Organization in advanced composite materials and sheet metal structures, as well as a Transport Canada Design Approval Organization. In addition to working with Canada’s flag carrier, the company has earned credibility with a variety of operators, and even major airframe OEMs like Airbus, Boeing, Collins, and Leonardo.

What is M1’s secret to success? Marandola explained that the company solves problems. “So, when others would look at a problem and say, ‘This may not be worth it,’ we excel at that and we’re able to take it to the next level with a complete solution.

“The model that we have is, instead of these operators or companies having their own backshop that does this type of work, we serve all of these companies that have the same requirement,” he continued. “And in that way, they’re actually sharing the costs, and they don’t have to hire all that staff.”

These days, M1 is offering a lot more than just composite repairs. The company has engineering and manufacturing capabilities when it comes to aircraft components. But most noteworthy is M1’s ability to predict the life of an aircraft part to save time and money in the long run. Marandola referred to this as a “life program,” where a part gets installed on an aircraft, it goes through the cycles of takeoff, climb, flight, and landing, and M1 is able to look at how that part on that aircraft will behave.

“We’re able to look at how that part will break and determine what the life of that part would be,” he said. “And in order to extend that life, how would we — in terms of engineering, maintenance, and repair — be able to keep that part going, and ensure that it’s always done safely?”

In addition to growing its capabilities over the years, M1 has also expanded beyond its civil aerospace customer base by entering the military sector. Today, the company does work for the Royal Canadian Air Force and U.S. Air Force, as well as Boeing Defense.

“The Canadian Forces will come to us and say, ‘We have a problem when we’re going into theater — we’re getting hit by rounds and we need protection in certain areas.’ And we come up with a structural protective solution. Or, it could be a mechanical system where we have to provide a rapid repair solution that they can apply in under two minutes; it would give them the necessary hours so they can get the aircraft back to the base where we can actually perform the repair completely.

“When we’re trying to find solutions for them, it’s to be able to save their lives, to bring them out of harm’s way and back home,” he added.

Looking back on the last 10 years, M1 has a lot to be proud of. A major achievement for the company was earning Mach 5 certification in February 2021, as part of Aero Montreal’s Mach Initiative for supply chain excellence.

“There are only two companies that are Mach 5, which is the highest level,” said Marandola. “The other is an American company, so M1 is the only Canadian company that made it to Mach 5.”

It wasn’t an easy road, he admitted, but it has pushed the company to continue to strive for excellence.

Among M1’s achievements, Marandola said there is one that stands out among the rest: earning the trust of both operators and OEMs.

“We’re not only doing repairs on aircraft that are in service, but we’re repairing products for aircraft that are being manufactured,” he said. “So even before they get to the customer, the OEMs have entrusted us with repairing or manufacturing parts. . . . That is something that we’ve worked very hard to attain.”

So, where does M1 go from here? Marandola hinted that there might be another expansion in the company’s future. With the globalization of both air travel and the type of work that M1 is doing, “we are definitely looking at other countries,” said Marandola.

While expanding into another country is on M1’s radar, Marandola said the priority for the time being is to make sure that the Canadian operation in Quebec works well.

“I think Canada has a lot to offer, and Quebec has a lot to offer in terms of aviation,” he added. “We have very highly skilled personnel here.”

No matter how much time goes by, one thing that will never change is the passion behind the work.

“What motivates me is, the products that we’re working on — be it the military products, or the latest and greatest aircraft, or legacy aircraft — they have to be something that we truly take passion in doing,” Marandola told Skies. “The job… the type of work here is truly a passion. And being able to work on these aircraft, I think, is a privilege.”