Estimated reading time 6 minutes, 58 seconds.

Although technology is steadily making the world smaller and more accessible, Machida Inc. still thinks big when it comes to finding new ways to solve customers’ quandaries and create a custom experience.

“We’ve been supporting the aviation industry for over 42 years now,” said Jitu Patel, vice president of Machida’s industrial division. The company has come a long way from its roots as a medical equipment-focused manufacturer in 1975, when it was founded as a joint venture between Katsumi Oneda and Tokyo-based Machida Endoscope Company, Ltd.

“We’ve been supporting the aviation industry for over 42 years now,” said Jitu Patel, vice president of Machida’s industrial division. The company has come a long way from its roots as a medical equipment-focused manufacturer in 1975, when it was founded as a joint venture between Katsumi Oneda and Tokyo-based Machida Endoscope Company, Ltd.

Patel, who has been with the company since its inception, recalls its initial move into the aeronautics industry by designing a flexible borescope for the Pratt & Whitney Government Products Division’s F100 engine.

“We used our experience in making medical bronchoscopes and the channel within it to get biopsy tissue and we created the six-foot borescope with a working channel for the F-15 and F-16 aircraft engines–all within 30 days,” said Patel. “Beside our standard models, we were the only people doing the custom designing at that time.”

“We used our experience in making medical bronchoscopes and the channel within it to get biopsy tissue and we created the six-foot borescope with a working channel for the F-15 and F-16 aircraft engines–all within 30 days,” said Patel. “Beside our standard models, we were the only people doing the custom designing at that time.”

The success of that initial design led to the creation of Machida’s industrial division which, over the years, has created borescope systems for the aerospace, automotive, aviation, casting, electronic, nuclear, petrochemical, power generation and refining industries.

Today, Machida’s work in the non-destructive testing (NDT) field is known for its custom approach in the developing of visual inspection instruments for both the military and commercial gas turbine engine market.

“We are known in the industry as the custom design people–we do a lot of custom work and resolve a lot of issues for engine companies or the aerospace industry,” said Patel. “Having the medical background and industrial background in our company allowed us to combine both technologies together.”

All of Machida’s borescopes are made at its facility in Orangeburg, New York, where the company is based.

All of Machida’s borescopes are made at its facility in Orangeburg, New York, where the company is based.

“Having everything here in the U.S. allows us to give a better customer service experience, so we’re able to not only react quickly, but we can get things expedited because we have those capabilities in house,” said Machida marketing and operations manager Jennifer Kempsey, who has been involved with the borescope industry since 2004.

“Whenever any of our customers have an AOG [aircraft on ground], we’re always quick to respond and get them something right away, and we do the best that we can internally here with our team to get the manufacturing done as quickly as possible because we understand the demand and requirements needed.”

That custom experience is based on the ingenuity and problem-solving capabilities of Machida’s engineers. “Every engine company will encounter some issues during the manufacturing or design process, and a lot of the time, they require something totally different that does not currently exist in the field,” said Patel. “We’ll get a call about these hurdles, and consult with our medical engineers and 99 percent of the time, we’ll come up with a solution.”

Patel pointed to solutions that Machida has worked out for clients, such as borescopes that allow mechanics to apply RTV through openings as small as six millimeters to avoid blade vibration within an engine, videoscopes with high resolution, medical grade cameras for smaller engines and components or borescopes which grind out blockages, vacuum debris or use black light to detect minute cracks.

Patel pointed to solutions that Machida has worked out for clients, such as borescopes that allow mechanics to apply RTV through openings as small as six millimeters to avoid blade vibration within an engine, videoscopes with high resolution, medical grade cameras for smaller engines and components or borescopes which grind out blockages, vacuum debris or use black light to detect minute cracks.

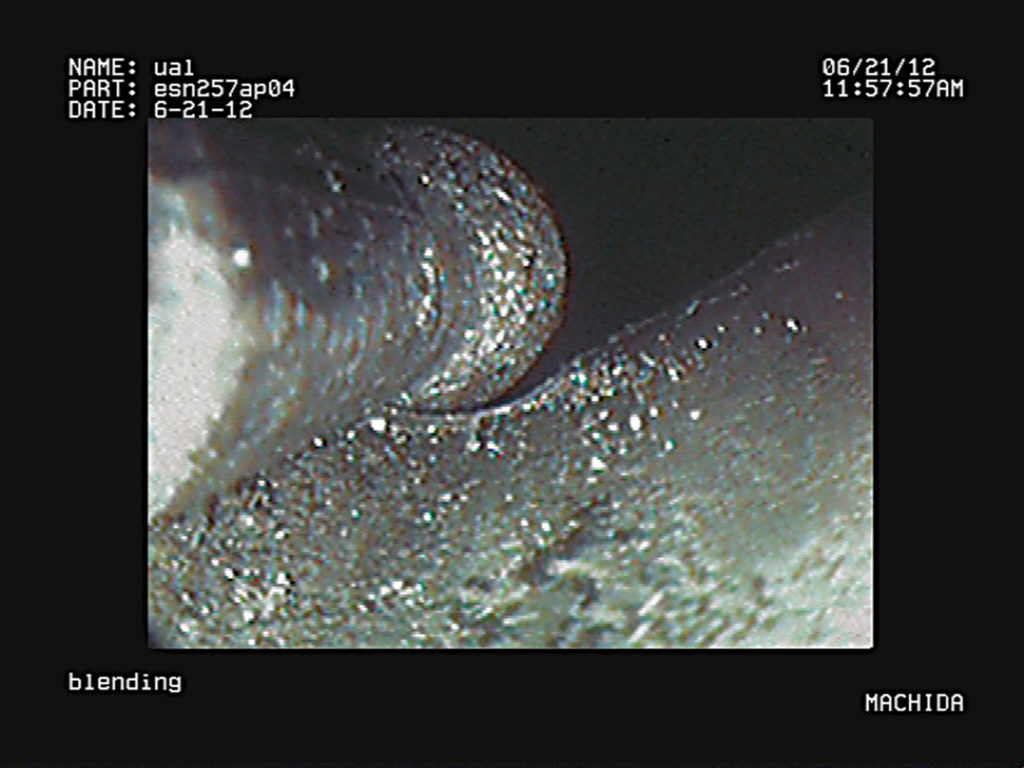

Products such as Machida’s power blending borescopes, which allow for reworking of nicks or dents on a blade while the engine is on the wing, also allow aircraft owners or engine companies to save time and money.

“Our borescopes offer a wide field of view and automatic light adjustment, allowing a clearer view. This cuts down on inspection time as it allows you to make the important decisions quickly and easily with confidence,” said Kempsey.

Regardless of the problem, Patel and his team relish the chance to solve it. “The more challenges we have, the more we study and investigate it and try to look at available techniques,” said Patel. “We’re staying in touch with the medical field constantly to see what they are doing so that we can use it in our field. Our custom work is setting the standards in many cases.”

Regardless of the problem, Patel and his team relish the chance to solve it. “The more challenges we have, the more we study and investigate it and try to look at available techniques,” said Patel. “We’re staying in touch with the medical field constantly to see what they are doing so that we can use it in our field. Our custom work is setting the standards in many cases.”

As part of that process, Machida also gives back by investing in industry education, whether through the glossary of terms on its website or through philanthropic efforts, such as sponsoring the Aerospace Maintenance Competition.

“It is important to us to get involved with future engineers and technicians to ensure they have the proper tooling in front of them, and prepare them for tomorrow’s workplace,” said Kempsey.

As a smaller company, Machida applies the personal touch to its customer base. “Our customers are our family,” said Patel. “Most of our customers are long-term. We’ve known them since the beginning and we’ve been able to continue to support them for many years.”

Many of those customers are at the National Business Aviation Association (NBAA) Business Aviation Convention and Exhibition, where Machida has been present for the last four decades, and both Patel and Kempsey look forward each year to supporting the industry and continuing those relationships.

Many of those customers are at the National Business Aviation Association (NBAA) Business Aviation Convention and Exhibition, where Machida has been present for the last four decades, and both Patel and Kempsey look forward each year to supporting the industry and continuing those relationships.

“We’ve been supporting NBAA for the last 40 years now, so our customers have seen us grow and develop and improve over time,” said Patel. “We take real pride when customers come to the booth and say they like the new products and developments. Our products tell them about what we do here–it’s not the number of employees but the talent and innovation that they bring that matters. We are presented with new challenges every day and our ability to provide solutions is what sets us apart.”