Estimated reading time 20 minutes, 36 seconds.

Skies rounded up some of the new technology in the aerial firefighting sector that you need to know about:

Conair’s Mission Training System (MTS)

Inspired by the air force and its military training simulators, Conair has developed a Mission Training System (MTS) that will revolutionize aerial firefighting training. The MTS is a Distributed Simulation System which allows individual flight training devices (FTDs) the ability to see the same terrain, weather conditions, and each other in flight. Each simulator has the ability to see the other’s water/retardant drops and communicate throughout the process. The system includes six integrated high fidelity simulators: two Bird Dogs (Cessna 208 or TC690); two air tankers (reconfigurable between RJ85, Dash 8-400); and two Air Tractors (both wheeled and Fire Boss versions of the aircraft type). The system’s simulated wildfire reacts to wind shift, humidity, terrain slope, and fuel type (grass, trees, etc.). In addition, the fire reacts to drops of water and retardant, so pilots and the air attack officer can practice as close to a real-life scenario as possible.

Director of business development, Jeff Berry, said, “What I’m most excited about is the ability to simulate the complex, overcrowded radio communications that happen over a fire, so that the first time a new pilot or air attack officer gets over a busy fire, it won’t be the first time they’ve had to sort out that noise, filter it, and set up their aircraft so that they can effectively communicate. That’s the first thing that usually collapses, is your communications.”

The MTS is designed specifically for aerial firefighting and is the first in the world of its kind. The project has been in development since 2016 and is planned to be fully operational by March 2022. This quantum shift in training will increase the number of hours that pilots spend in training and will support pilots as they learn valuable experiences in a controlled environment.

CarteNav AIMS-C4 system

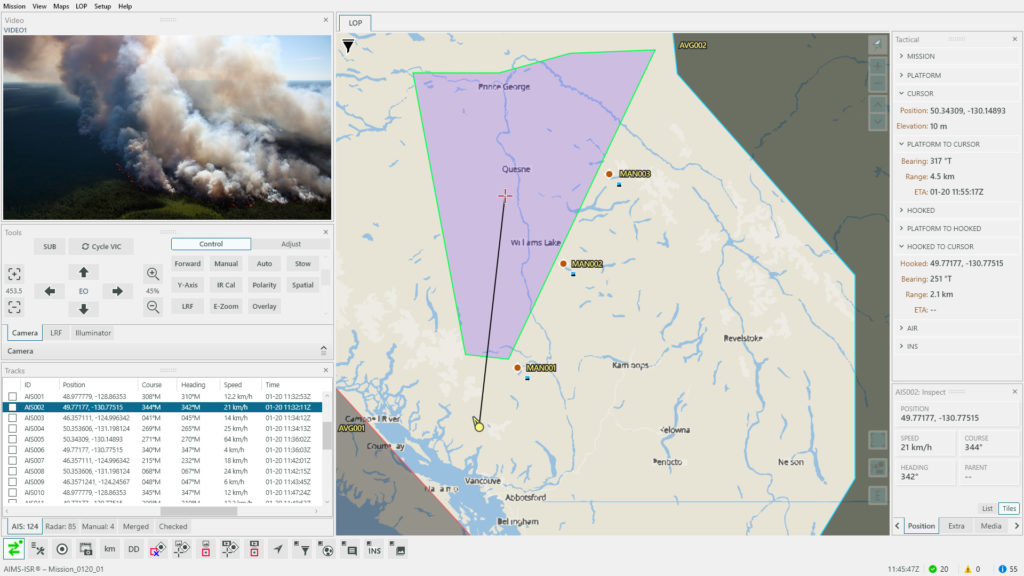

CarteNav, a Canadian company based out of Halifax, Nova Scotia, is one of the first to apply augmented reality mapping to aerial firefighting and surveillance technology. Its AIMS-ISR software has been used for the last decade by companies around the world, and CarteNav is now in the testing phases of its AIMS-C4 mission data distribution system — which will compliment the existing mission system software.

Trevor Bradley, director of marketing, said, “With our software, operators have the ability to get the geo-physical representation of the fire on their screens. They can trace the fire perimeter with the camera boresight, or draw it manually using the live video as a reference to create an accurate perimeter. They can also provide mean speed of advance calculations of the leading fire edge, and allow the operators to apply custom symbology to really focus in on the hotspots. All the data created can be shared live with command and control centers, allowing crews on the ground to respond quickly and save lives.”

Along with accurate mapping, AIMS-ISR also assists in pre-mission planning and post-mission debriefing and analysis. The tools are complimentary to multi-mission operations related to aerial firefighting, search-and-rescue, and law enforcement.

Tim Hand, manager of special projects, Heliwest, said: “With AIMS-ISR, we can provide highly accurate, near-real-time maps of the current fire situation to planners and firefighting teams on the ground. Without it, that would be impossible.”

AIMS-C4 is an emerging technology that compliments the existing AIMS-ISR mission system. It allows operators to manage missions from an intuitively powerful web interface. AIMS-C4 allows real-time communication and data-sharing between operators, analysts, and decision makers. It is a data management and distribution system that allows operators to log all the existing fires, as well as assets and evidence, such as imagery, communications, video, and post-fire damage. Operators can also see how the fire is moving and changing on the map. CarteNav strives to create the maximum situational awareness for its customers and continues to push toward advances in the field of aerial firefighting technology.

CO Fire Aviation Air Tractor night ops

CO Fire Aviation, a Colorado-based company founded by pilots Chris Doyle and Kyle Scott, is the first and only operator to install night vision technology in Air Tractors for the purpose of agricultural aerial application and aerial firefighting. Their team of ex-military pilots understood the benefits that night vision technology could bring to aerial operations because of their personal experiences during many combat missions. With night vision tech becoming available to civilian operators and more advanced software being developed, CO Fire made the decision to invest in the future.

The company partnered with Aviation Specialties Unlimited to create night vision goggles (NVGs) and facilitated the modifications needed for the Air Tractor AT-802F. This technology allows pilots to see power lines, structures, and terrain clearly at night. Some of the advantages to fighting fires at night include: lower temperatures, an increase in humidity, and calmer winds. The technology also makes it easier to identifying hot spots, allowing pilots to eliminate the risk of new fires starting up.

CO Fire was contracted by the Oregon Department of Forestry last year, where it was able to conduct testing and training. The feedback was very positive, and the company is hoping to gain real-world operational experience using its NVGs this fire season. Of its fleet of nine Air Tractor AT-802Fs, two are outfitted with NVG technology. CO Fire has been operating at night for its agricultural applications for three years and has had an incredibly positive impact.

Founder, Chris Doyle, said: “This technology increases the safety, effectiveness, and productivity on the crop dusting side for sure.” CO Fire’s main purpose now is to prove that the technology works, and show that it is safe and effective in aerial firefighting operations.

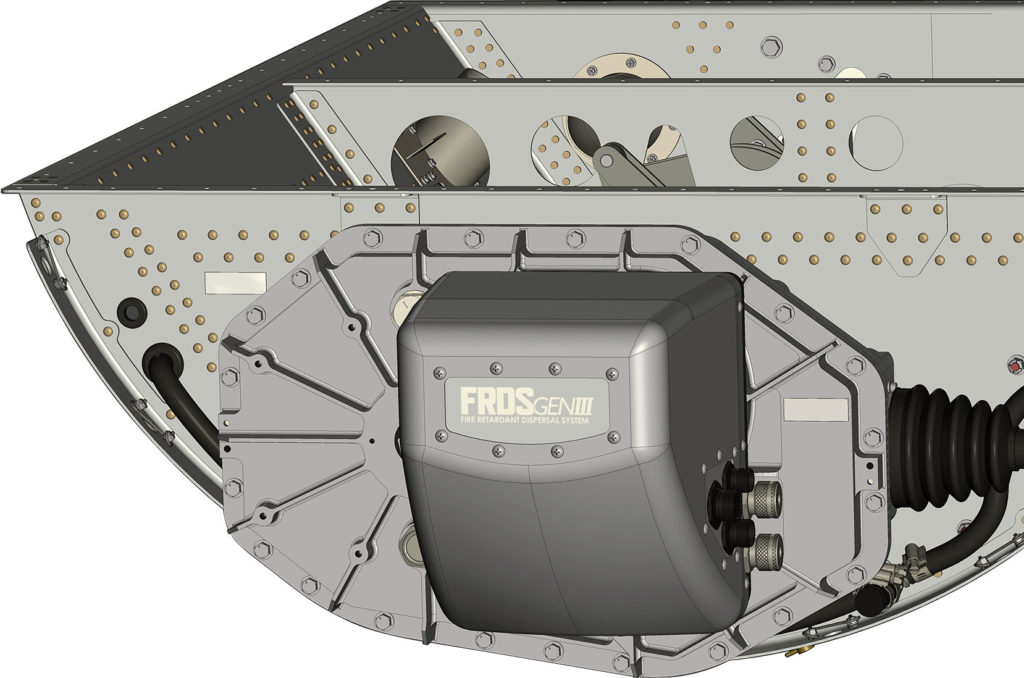

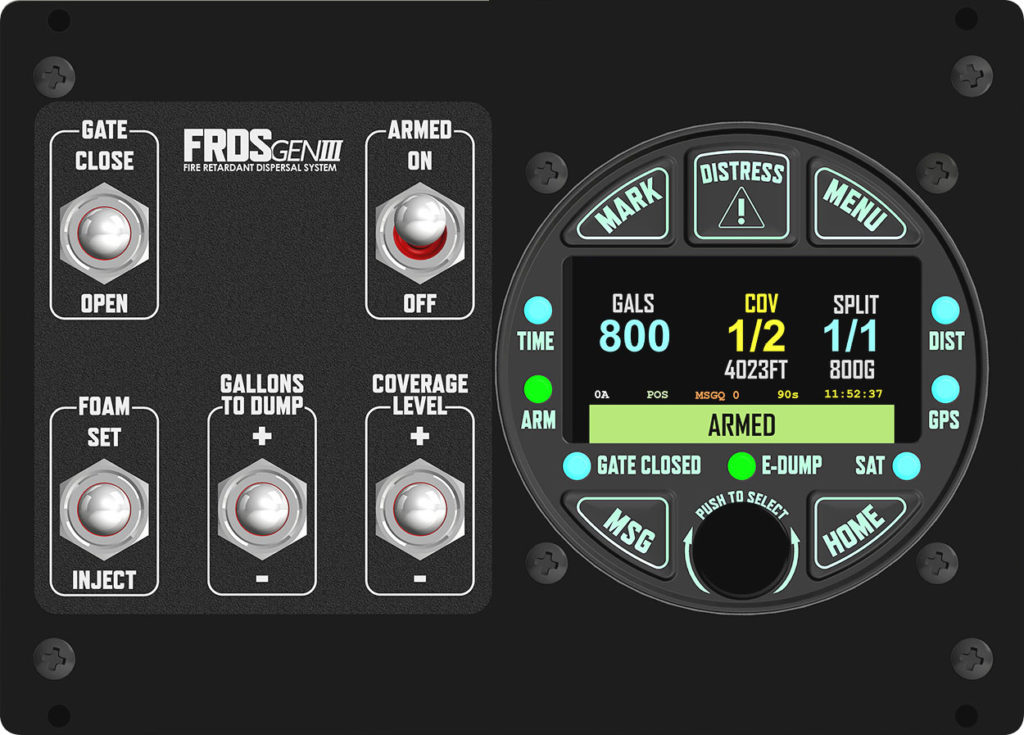

Trotter Controls’ all-electric firegate system

Trotter Controls provides product design, system integration, and repair services for the aerial mission equipment industry, in addition to automation services. Its focus has been on designing and building electronics — as well as the mechanical systems used — in the aerial firefighting and aerial agricultural industries. The Fort Worth, Texas-based company began working with its partner, Air Tractor, to develop a cutting-edge, all-electric firegate system in 2018. Trotter Controls’ Fire Retardant Dispersal System (FRDS) Gen III is a lightweight, all-electric OEM firegate built for the Air Tractor AT-802F aircraft.

Victor Trotter, owner and president of Trotter Controls, was one of the primary design engineers on the first Air Tractor 802F, specializing in controls and hydraulics. FRDS Gen III allows operators to bypass all the flammability issues of hydraulics, pressure containment problems, and other complex systems issues, and replace them with a fairly simple electric motor and gearbox.

“For one system we designed, we saved over 270 pounds,” said Trotter. “There is no hydraulic system, no oil reservoir, no hoses, no valves… so it’s kind of a big deal in terms of weight savings.”

This system has received FAA STC approval and is now available for factory Air Tractor installation or retrofits.

There is a constant flow algorithm associated with the system, which maximizes the distance the aircraft can cover on the ground with fire retardant for a given amount of available retardant. The company’s DataVault system transmits location and operational data to fire services in near real time. This information includes: drop start/stop locations, GPS path, quantity, retardant on board, engine start and flight time, and much more. Overall, more power density and efficiency is gained anytime an electric-to-hydraulic conversion can be avoided.

New in 2021, Trotter Controls has applied for patents for an “all-electric agricultural gate system,” as well as a patent for a “constant flow” helicopter bucket system. The company has shipped 31 FRDS Gen III systems since last March, and expects to keep busy with these systems in the future.

AeroBrigham/MyGoFlight Fire Boss HUD

Aerobrigham, a maintenance, completions, and refurbishing company based in Decatur, Texas, is the first to install a head-up display (HUD) enhanced vision system (EVS) for use in the Air Tractor Fire Boss. The Fire Boss HUD EVS is the first of its kind, and is being installed in partnership with MyGoFlight — the company that developed the system, which is called SKYDISPLAY.

The SKYDISPLAY HUD EVS technology has the ability to display traffic, weather, and terrain from a thermal imaging camera, as well as critical flight information from the avionics. The SKYDISPLAY system is integrated with the Max Vis EVS 600 thermal imaging camera and the complete Garmin glass display. Four units are currently in service with Dauntless Air — a large, U.S.-based aerial firefighting operator with a total of 17 aircraft. All four aircraft with newly outfitted HUD systems will be in active service this fire season, and the operator is already noticing a greater success rate with water drops since starting to use the technology.

David Brigham, president and CEO of AeroBrigham, said: “This system gives the pilots tremendous situational awareness, making it easier to see where they are in relation to terrain and trees; it also helps them identify hotspots through the smoke. The head-up display puts the thermal imagery right in front of their eyes instead of having to glance to the side.”

As of right now, the system is certified to display the thermal camera imagery, however, MyGoFlight is in the process of getting STC approval for primary flight instrument information to also be displayed. This technology is pushing the capabilities of aerial firefighting; single-engine airtankers, like the Fire Boss, are gaining in popularity because of their ability to get from point A to point B and tackle smaller fires before they get out of hand.

Aerobrigham is looking forward to seeing how this technology grows in the space and how it can be applied to so many different niches within the aviation industry. On the Air Tractor alone, there are additional opportunities in agriculture spraying and mosquito control operations. If interested in exploring how the MyGoFlight SKYDISPLAY HUD EVS can help your operations, contact David at david@aerobrigham.com. To learn more about MyGoFlight’s SKYDISPLAY HUD EVS system, visit www.SKYDISPLAY.com.

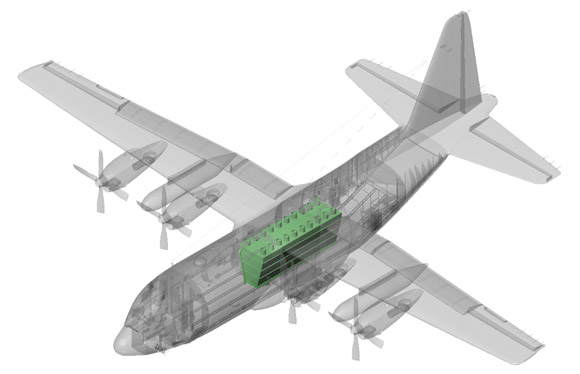

Coulson Aviation’s Retardant Aerial Delivery System (RADS)

Coulson Aviation is a big player in the aerial firefighting industry and is continuing to push the envelope by developing new technologies. The company’s team works tirelessly to be the premiere provider of aerial firefighting tech. Now, Coulson is outfitting its Retardant Aerial Delivery System (RADS)-XXL in six C-130s and six 737 Fireliners.

The original tank was designed and certified in the ‘90s and was the first constant flow firefighting system in the world. Coulson purchased the RADS one tank STC from Aero Union to start off its latest generation of tank data. Coulson soon noticed many optimization opportunities when it started working with Lockheed as the OEM of the C-130 Hercules. The company redesigned the system into what it has today, and in 2014 it became the newest large airtanker tank design in the world. Coulson’s systems integrate with the GPS ground speed and the radar altimeter to increase or decrease flow rate, so that pilots can ensure the right amount of product hits the ground based on the needs of the mission.

Britt Coulson, president of the Coulson Group, said, “Our controller and cockpit interface provides operators with real-time flow rate adjustment technology, resulting in superior drop zone coverage and accuracy.”

Coulson has transferred the RADS-XXL design onto the Boeing 737 Fireliner, the first split-tank design ever. In doing so, the company has created the fastest, highest flying airtanker in the world. All RADS systems run the same drop controller and hydraulic systems, and Coulson continues to refine and improve it, depending on the installation platform. RADS-XXL has a flow rate of 1,600 gallons per second, emptying out in as little as 2.2 seconds and carrying up to 4,000 gallons of retardant — the very first constant flow firefighting system in the world. As time passes and technology evolves, Coulson looks forward to being at the forefront of the aerial firefighting tech sector.

You forgot about MAFFS which is better tech than RADS in fact. You should have included.