Estimated reading time 6 minutes, 32 seconds.

Boom Supersonic, the company behind the development of the world’s fastest airliner, has made significant progress on its sustainable supersonic aircraft, Overture — which is designed to carry 65 to 80 passengers with the ability to fly Mach 1.7 over water and Mach 0.94 over land. The aircraft is expected to have a 4,250-nautical-mile range (with full payload) with the ability to run on 100 percent sustainable aviation fuel (SAF).

Boom shared several program updates during this year’s Paris Air Show, including its selection of structure suppliers, its vision for Overture’s systems configuration, new milestones with its Symphony engine, and its collaboration with Northrop Grumman on a NASA contract.

Boom has signed agreements with various aerospace companies for the supply of key components for its supersonic airliner. Aernnova will provide the wings, Leonardo will supply the fuselage and wing box, and Aciturri will be responsible for the empennage. These companies join Boom’s existing network of suppliers, which includes Safran Landing Systems, Eaton, Collins Aerospace, Flight Safety International, Florida Turbine Technologies (FTT), GE Additive, and StandardAero.

Moreover, Boom shared a comprehensive look at the systems configuration of Overture, showcasing avionics, flight controls, hydraulics, fuel systems, and landing gear. Specifically, the fuel systems enable center of gravity control during subsonic and supersonic flight, support the use of SAF, and supply fuel to the engines. Boom says “triple redundant hydraulic systems provide reliable power for flight controls and mechanical systems,” while the landing gear is compatible with international airport runways and taxiways.

Overture’s gull-shaped wings are to be designed and developed by Aernnova to enhance supersonic performance and improve handling at subsonic and transonic speeds.

“The wings are structurally thinner than typical subsonic wings to reduce drag, allowing the aircraft to efficiently travel at higher speeds,” noted Boom.

The fuselage, to be designed and built in partnership with Leonardo, is contoured, meaning it has a larger diameter towards the aircraft’s front and a smaller diameter towards the rear. Boom said this design technique was implemented to reduce wave-drag and optimize fuel efficiency during supersonic flight.

Overture’s empennage, to be designed and developed by Spain-based Aciturri, features a distinct horizontal stabilizer that enhances control, particularly during subsonic maneuvers such as takeoff and landing.

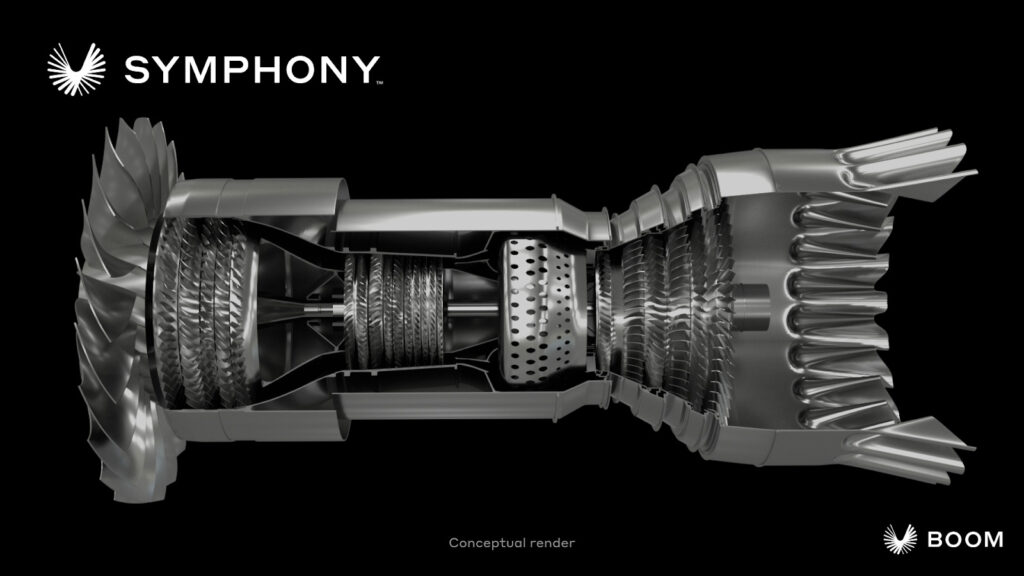

Additionally, the engine design for Overture has hit new program milestones. Boom announced in December 2022 that it has partnered with three aerospace companies to develop a new propulsion system, known as Symphony, for its supersonic airliner. Developed in collaboration with FTT, GE Additive, and StandardAero, Symphony is a two-spool, medium-bypass turbofan engine (no afterburner) that features the same basic engine architecture found in modern commercial aircraft, but with a few differences. The first is an axisymmetric supersonic intake, to be designed by Boom, as well as a variable-geometry low-noise exhaust nozzle and a passively cooled high-pressure turbine.

During the Paris Air Show, Boom unveiled a 3D-printed one-third-scale model of Symphony and announced that it has expanded its partnership with FTT to assemble the initial production units for ground test, flight test, and certification. Jupiter, Florida, will serve as the base for initial production.

The company noted that the engine — which delivers 35,000 pounds of thrust — is optimized for sustainable supersonic flight, providing 25 percent more time on wing and 10 percent operating cost savings to airlines. According to Boom, Symphony is compliant with FAA and EASA Part 33 requirements.

“We are incredibly proud of the progress with Overture and Symphony from our global team of partners and suppliers who continue to operate at an accelerated pace toward the future of sustainable supersonic flight,” said Blake Scholl, founder and CEO of Boom Supersonic.

Lastly, Boom shared an update on its collaboration with Virginia-based aerospace and defense company Northrop Grumman. While the two companies are continuing to work on a special mission variant of Overture, they are also collaborating on a NASA contract to explore technologies for the advancement of commercial supersonic flight efficiency — as part of the “High-Speed Endo-atmospheric Commercial Vehicle Conceptual Design Study and Technology Roadmaps Development” program.

“Initial technologies to be explored include mechanisms to increase aircraft efficiency and reduce emissions, net CO2 reduction, net non-CO2 reduction, and climate feedback loops,” said Boom.

Currently, the commercial order book for Overture stands at 130 aircraft, including orders and pre-orders from major airlines such as United, American, and Japan Airlines. Boom is aiming for production of Overture to begin in 2024 at the Greensboro-based Overture Superfactory, with rollout in 2026, first flight in 2027, and certification in 2029.

WoW!!

David Baker

Carson City, NV