Estimated reading time 15 minutes, 31 seconds.

New engine technologies and creative aerodynamic designs have long allowed entrepreneurial engineers to enhance the performance and efficiency of mature aircraft models. A case in point is the latest modification of the de Havilland Canada DHC-2 Beaver by Sealand Aviation of Campbell River, British Columbia. This venture involves the installation of a V-12 piston engine that consumes diesel or Jet-A fuel. Before going into more detail, it is worth reviewing the aircraft type selected for the project.

The aircraft

The prototype DHC-2 Beaver first flew on Aug. 16, 1947. When production ended in 1968, 1,692 units had been built. This included 1,631 Mk. I models equipped with 450-horsepower Pratt & Whitney R-985 Wasp Junior radial piston engines. Serial number 80 became the only Mk. II model when its R-985 was replaced by a 550-hp Alvis Leonides 502/4 radial in 1953. That engine was in turn replaced in 1985 when AirTech Canada installed a 600-hp PZL-3S radial.

DHC produced 60 Mk. III Turbo-Beavers between 1963 and 1968. They were equipped with 578-hp Pratt & Whitney Canada PT6A-6 turbine engines.

Since then, many Mk. Is have been modified with different versions of the PT6A. Further, two examples are equipped with Garrett TPE331 turbines. One modification was performed by Volpar of Van Nuys, California, and the other was done by S.W.P. Aircraft Engineering at Bankstown, Australia.

Clearly, the DHC-2 airframe has proven to be compatible with various engine models. Now, a sixth engine model has been selected to power the venerable veteran.

The engine

Founded in 2008, Raikhlin Aircraft Engine Development (RED Aircraft) of Adenau, Germany, has developed a family of V-12 piston engines. The private company’s goal has been to produce engines that are more fuel efficient, produce less exhaust gas emissions, and are quieter.

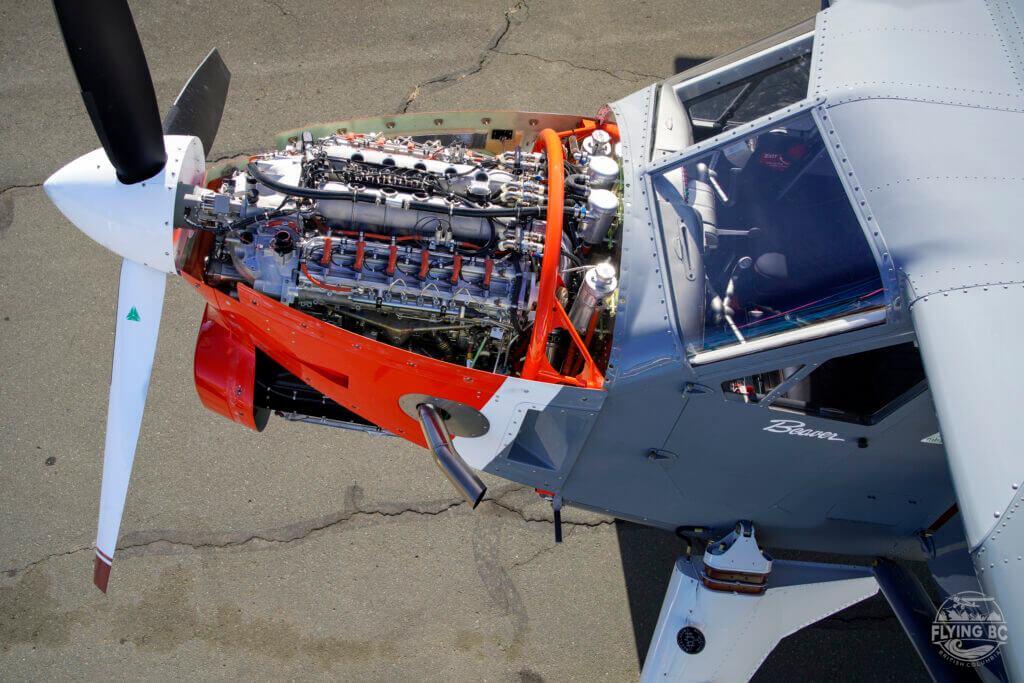

The first variant of its A03 model was certified in December 2014. Sealand Aviation describes the RED A03 as, “a lightweight, all-aluminum, compression-ignition, internal-combustion, 12-cylinder engine in an 80-degree V configuration with two six-cylinder banks that are capable of independent operation.”

The model selected for the DHC-2 modification by Sealand is the RED A03-005. According to the European Union Aviation Safety Agency (EASA) type-certificate data sheet, it was certified on June 30, 2022. It later received its Federal Aviation Administration (FAA) certification on April 7, 2023. The EASA data sheet notes that the engine can produce 550 hp/405 kW during takeoff; 460 hp/338 kW at maximum cruise speed; and 400 hp/294 kW at economy cruise speed. It weighs 800 pounds (363 kilograms), and it is equipped with a full authority digital engine control (FADEC) system. This provides operators with real-time engine data so that maintenance requirements are known quickly and downtime can be minimized.

The project manager

Sealand’s president, Bill Alder, founded the company in 1981. Since then, it has maintained, repaired, rebuilt, and modified many Beavers. It has developed and obtained supplemental type certificates (STCs) for numerous DHC-2 modifications, including its cabin extension and large cargo door kits. The company has extended the cabins of more than one-third of the Beavers currently in service. Given its experience, it makes sense that Sealand would be interested in matching a new engine design with this iconic airframe.

The prototype

DHC-2 serial number 690 began its career as 53-3732 with the United States Army on Sept. 1, 1954. After its military service, it flew with civilian operators in Minnesota, Alaska, and Hawaii before returning to Canada in 2019. It was registered to Sealand on June 12, 2020, and shipped to Campbell River, where a RED A03 engine was installed.

Since then, the avionics have been upgraded, the cabin has been refurbished, and the exterior has been dressed in an eye-catching paint scheme. The aircraft flew for the first time with the RED engine on Feb. 23, 2023, at Campbell River.

The outlook

To learn what is in store for this endeavor, Skies reached out to Sealand’s Alder.

SKIES: Where is the RED A03-005 engine certified?

ALDER: The engine has EASA and FAA type certificates and Transport Canada is in the process of issuing the Canadian type certificate.

SKIES: How many units of the RED A03 have been produced so far?

ALDER: Over 100 engines have been manufactured. According to the manufacturer there are 22 ongoing conversion and new aircraft projects underway or under consideration.

SKIES: Of the other aircraft types (Air Tractor AT-301, Cessna 208, etc.) using the RED A03, have any of those modifications received an STC?

ALDER: None have been STC’d yet. The installation in the Beaver will be the first one.

SKIES: Are any significant modifications to the DHC-2 airframe required for your project?

ALDER: Yes. Since this is a FADEC-controlled engine, without a mechanical override, there is a requirement for redundancy of the electrical system. The fuel system is modified as to a system that is very similar to the Turbo Beaver. Structurally, the only modification will be firewall forward — the engine mount.

SKIES: How long would it take to convert a stock DHC-2 Mk. I into the RED configuration?

ALDER: That is not easy to answer. It will depend on the configuration of the aircraft when we receive it and what the customer’s expectations are.

SKIES: What would the price be for a customer who already possesses a DHC-2?

ALDER: Right now, we are quoting US$650,000.

SKIES: What would the purchase price be for a customer who doesn’t own a Beaver?

ALDER: I expect the price will be in the US$1.3 million range for us to supply an aircraft with the RED engine STC, plus most of the other desired modifications like gross weight increase and Alaska door. The price will vary depending on the customer’s expectations.

SKIES: How large is your target market?

ALDER: I believe this modification will extend the operational life of the Beaver. It is such a remarkable aircraft and with the better fuel economy and speed the RED provides, it will be a desirable aircraft. There is the potential to do 200 aircraft.

SKIES: Once the STC has been granted, how many modifications could Sealand Aviation perform per year?

ALDER: We are already scheduled to do five aircraft the first year. One customer has booked two aircraft per year for the next five years. Forever the optimist, I believe we can meet the demand.

SKIES: What sort of performance are you expecting from a RED-powered Beaver?

ALDER: On wheels, a cruise speed of 140 mph, a useful payload (depending on gross weight mods) of over 2,500 lbs., a maximum range of 7.5 hours, with a fuel burn of 10 to 20 gallons/hour depending on how fast you want to go. The engine’s time between overhauls is currently 2,000 hours with the expectation of up to 3,000 hours. I compare the RED Beaver to a Cessna 206 — same speed, same fuel consumption, but up to three times the payload.

SKIES: What are the key milestones that need to be reached in obtaining an STC for this project from Transport Canada?

ALDER: Proof of concept has been completed and is very satisfactory. Type board meeting with Transport Canada was held in Ottawa last month, and we now know what the expectations are. We have contracted with several Design Approval Representatives (DARs) to set up and complete the required testing.

SKIES: How long might the STC process take?

ALDER: We expect the STC to be approved during the first quarter of 2024.

SKIES: How much capital is required to fund this STC program?

ALDER: It is significant for a relatively small company like Sealand Aviation.

SKIES: Has the required funding been sourced?

ALDER: We are still working on that. Our prototype is up and running and it has exceeded our expectations. We have sales in the pipeline, so we are bankable.

SKIES: Harbour Air’s eBeaver prototype with the magni350 electric propulsion unit received attention when it first flew three-and-a-half years ago. How will the RED Beaver compete with that model?

ALDER: Obviously it will not compete with an electric aircraft, but I think it is a great step forward. The reduced fuel burn to get the same or better airspeed and the fact that there are no lead emissions is a significant step forward environmentally. The engine is approved to burn sustainable aviation fuel (SAF) and we are looking at some biofuel options. This should fill the gap until there is a viable electric aircraft with similar speed, range, and payload.

Final thoughts

According to the Transport Canada and FAA civil aircraft registers, there are currently approximately 300 Wasp Junior-powered Beavers in Canada and another 350 in the U.S. Given the potential performance and economics of Sealand’s RED Beaver, it could prove to be an environmentally friendly solution for DHC-2 operators who are monitoring the future availability — let alone legality — of 100 low lead avgas.

Mr Larkin,

This is a concise and fascinating insight into a Canadian icon that grows better with international adaptations. Your last photo, with the big jib draw air intake, looks wonderfully turbo for the high payload practicality. Good work!

Robert Rutherford, Nova Scotia

Many thanks Mr. Rutherford for your positive feedback. It is an interesting design that will hopefully receive approvals from aviation regulatory authorities and orders from aircraft operators.

That RED engine is quiet amazing. Its actually designed by a Russian who established the company in Germany to avoid all the pitfalls of being a Russian company doing international business.