Estimated reading time 9 minutes, 20 seconds.

When you hear the word “carbon” these days, it’s almost immediately associated with “emissions.” In the aviation industry, in particular, carbon is a dirty word – something that must be eliminated, reduced, captured, or offset.

But what if the world’s existing carbon could be transformed into products we use every day? That’s the goal of Twelve, a Berkeley, California-based company founded in 2015 and named after the Carbon-12 isotope, which makes up the vast majority of naturally occurring carbon.

“Carbon transformation is our mission,” explained Ram Ramprasad, Twelve’s chief commercial officer. “We know the world runs on hydrocarbons, and most materials are made from hydrogen and carbon. Most of the carbon comes from mining fossil fuels. But we believe the carbon that already exists in the world can be reused and transformed into products – some into long-lasting products like plastics and some into fuels.”

Twelve uses a proprietary polymer electrolyte membrane (PEM) electrolyzer that works like “industrial photosynthesis” to break down CO2, water, and renewable electricity – recombining the elements into new chemicals, materials, and fuels that have traditionally been made from refined fossil fuels.

The company has made small proof of concept batches of an ingredient used in Tide laundry detergent and plastic parts for Mercedes-Benz vehicles.

Twelve doesn’t capture the carbon itself, but Ramprasad noted exciting developments in the field of direct air capture, or DAC. Companies are finding new ways to extract and capture CO2 from the air around us, and carbon taken from the air is a limitless feedstock for the creation of many products.

One of Twelve’s most promising breakthroughs is E-Jet® fuel, a fossil-free jet fuel that is made from electrified CO2.

“The difference is primarily the source of the carbon,” explained Ramprasad. “You need a carbon source if you don’t want to use fossil fuels. We start with CO2. The ‘E’ in E-Jet stands for electricity. We break the CO2 molecule into pieces by energizing it with electricity. It reacts and creates other molecules.”

He said the process has been proven in the lab and the technology is now being scaled up.

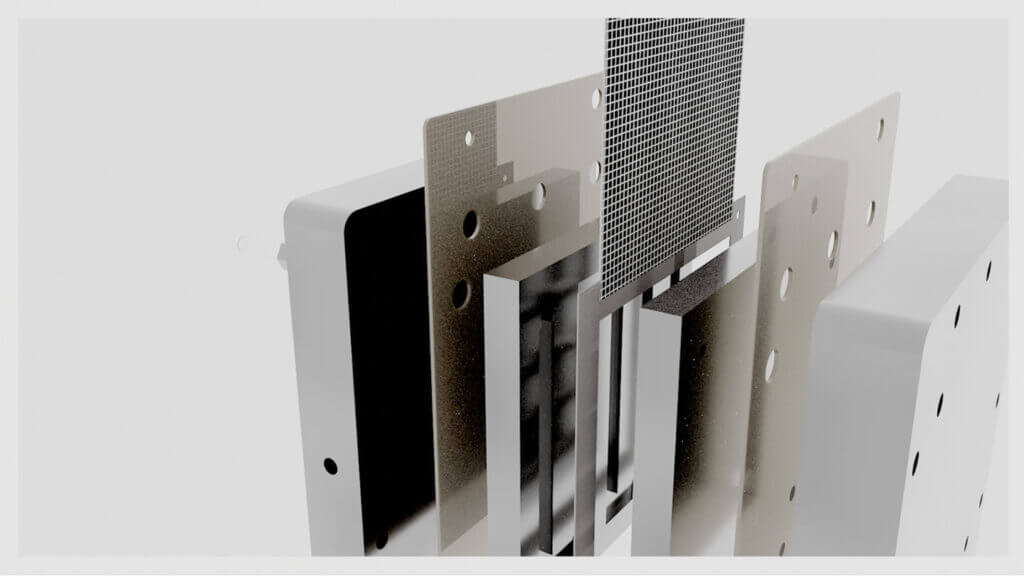

“We have now our first pilot plant, where the electrolyzer module is in long-term testing,” said Ramprasad. “The PEM membrane is really a thin membrane on either side of which the reaction happens, where the CO2 is broken up. We have to scale up by stacking them into a larger core module, which is now being tested. The next step after that is taking many of those modules and producing large volumes of the fuel.”

Twelve says that E-Jet offers up to a 90 percent reduction in lifecycle CO2 emissions, while other SAF products are in the 60 to 80 percent range. It is currently certified for flight at blend ratios of up to 50 percent with conventional fuel.

The company is now building a production site in Washington State, where it plans to produce larger amounts of E-Jet fuel. By this time next year, said Ramprasad, Twelve will have enough fuel to power flights. The first commercial demonstration flight will be operated by Alaska Airlines, which partnered with Microsoft and Twelve last July to advance the market for SAF derived from recaptured CO2.

“Microsoft and brands like it want to reduce the carbon footprint of their travel,” explained Ramprasad. “We’ve been talking to many of these corporations. They buy plane tickets from airline partners like Alaska Airlines and that’s how this came about. E-Jet fuel will be supplied to Alaska Airlines, and Microsoft is helping to defray the costs.”

In order to mass produce E-Jet fuel, Twelve will require a supply of captured carbon and renewable power.

“It’s only sustainable if we use renewable electricity to break up that CO2 molecule,” noted Ramprasad. “We are also looking for biogenic sources of CO2 from fermentation processes, such as pulp and paper production and landfill gases.”

He said Twelve hopes to build its next plant in 2025, and is finalizing the location over the next few months. It will be powered by water- or wind-generated electricity.

Experts have said that SAF represents the single biggest weapon in the arsenal when it comes to a greener future for aviation. Aircraft fly for a long time, which makes SAF the ideal solution because it can be used today in existing planes.

“That is the way to decarbonize most of aviation,” said Ramprasad. “Any new technology, such as hydrogen as a fuel, will require changes to aircraft engines. However, there currently is not enough SAF to go around, and all the airlines have their own intentions to decarbonize. There is a lot of interest in E-Jet fuel and it’s primarily coming from their customers, the end users.”

He is encouraged by recent incentives contained in the U.S. Inflation Reduction Act, as well as selected local programs, which support SAF development and carbon capture.

By 2050, Ramprasad believes the power-to-liquids pathway – which uses renewable electricity and recaptured carbon from the environment to make liquid fuels – will prove to be a more scalable method of mass-producing sustainable aviation fuel.

“It’s a very exciting time,” he concluded.